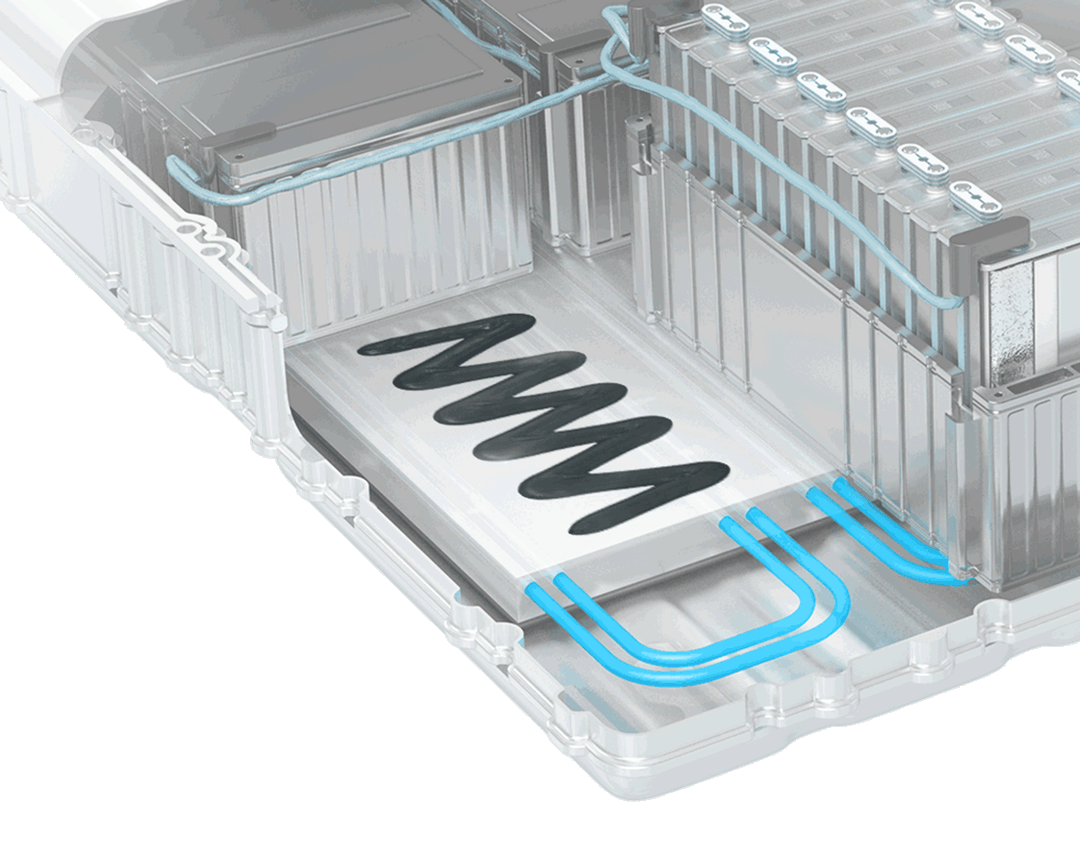

EV electronics

Mobility is going through a period of upheaval right now, with digitalization, electrification of the powertrain and autonomous driving the major factors. More and more electronic components are therefore needed, all of which have to be protected. Protection that can mean the difference between life and death. The key to their reliability is the correct application of the necessary sealants and adhesives, potting compounds and heat conducting pastes.