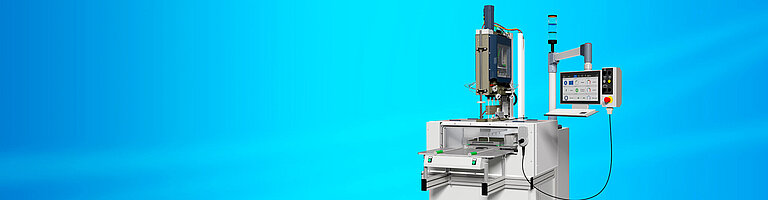

Quality and performance for the most demanding requirements

Increasing quality requirements and workpiece complexity or added degrees of freedom in design and engineering are just some of the many reasons to choose vacuum potting. Scheugenpflug vacuum dispensers were designed for cost-effective batch production at the highest levels of quality. All VDS systems feature a dispensing unit for 1C or 2C potting media, depending on your needs. To ensure bubble-free feeding of the potting medium, one of the LiquiPrep LP804 preparation and feeding systems is used. Powerful vacuum pumps evacuate the entire space around the component or components. This guarantees bubble-free and homogeneous filling of the components in order to achieve the required potting quality even for the most difficult dispensing tasks. To meet this requirement, various cost-effective models are therefore available both as standalone systems or for integration in a production line.

Advantages and Key features

- Short cycle times by potting multiple components per evacuation

- High component quality despite complex geometries and programming

- Indispensable for safety-relevant and highly functional components

- Dispensing contours under vacuum with XYZ axis system

- Powerful vacuum pump for effective evacuation

- Heated dispensing unit and tubes

- Intuitive operation and dispensing program setup with visualization UViS 5

Power to make time less of a limitation

Time can be a limiting factor for many reasons. This problem can be easily overcome with the VDS P(ower) vacuum dispensing system, which is usually equipped with three motion axes, an automatic cup position and a multi-piston dispenser (2 to 8 nozzles, depending on required performance; other sizes available upon request). In a single evacuation cycle, as many components as possible are processed at the same time on an even grid so that one dispensing stroke processes several workpieces at once. This system is the perfect solution for fast, premium quality potting of medium-sized or small components at very high production volumes.

Automated weighing - Inline

Automatic, quick and easy. For even greater reliability in vacuum dispensing. And fewer rejects thanks to consistent dispensing quality. Thanks to the inline needle and weighing control, time-consuming weighing outside the vacuum cell is no longer necessary. Fully automatic system so no pause in production.

Powerful software

The Universal Visualization UVIS 5 software offers a powerful user interface tailored to the application for all Scheugenpflug cells, vacuum dispensing systems and Scheugenpflug’s ProcessModule. The user always has an overview of the relevant data for all processes as well as associated monitoring, maintenance and analysis tasks.

Quick overview

++ = very good + = good (+) = limited − = not recommended

Compatible dispensers

Vacuum chamber dispenser 4 to 12 nozzle dispensing

(all feature 1-nozzle dispensing only)