How does adhesive bonding work?

Bonding is a technique for joining two or more parts using an adhesive substance. Hybrid processes, in which bonding is supplemented by a further operation such as sealing or heat dissipation, are becoming increasingly important in addition to standard bonding applications. They offer many advantages including simpler component handling and weight savings, as mentioned above, which is why they are supplementing or replacing more and more classic joining techniques such as welding and bolting in the industrial sector.

In industrial applications, the dots or lines of adhesive often have to be applied at precisely defined locations on or in the components to be joined. For this reason, highly viscous 1K or 2K adhesives based on polyurethane, silicone or epoxides are usually used as they will not run. Depending on the application and the bonding properties to be achieved, low-viscosity adhesives may also be the materials of choice.

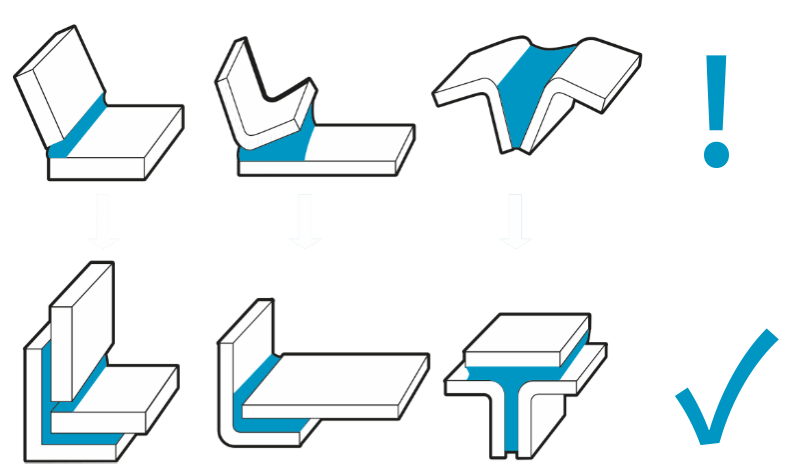

The sequence is always the same: apply evenly – match – bond. The adhesive should be applied as evenly as possible, and the bead diameter and length should be matched to the adhesive joint. The parts that are to be bonded with adhesives and cross-linked under the influence of moisture must be combined before the adhesive has formed a skin. What’s more, the pressure must be as uniform as possible.