Use potting experience and know-how at the component design stage

Want to learn more about potting-optimized component design? Find the answers in our new whitepaper.

Download it now here:

What requirements do engineering and design have to meet?

Designers have great responsibility toward the product.

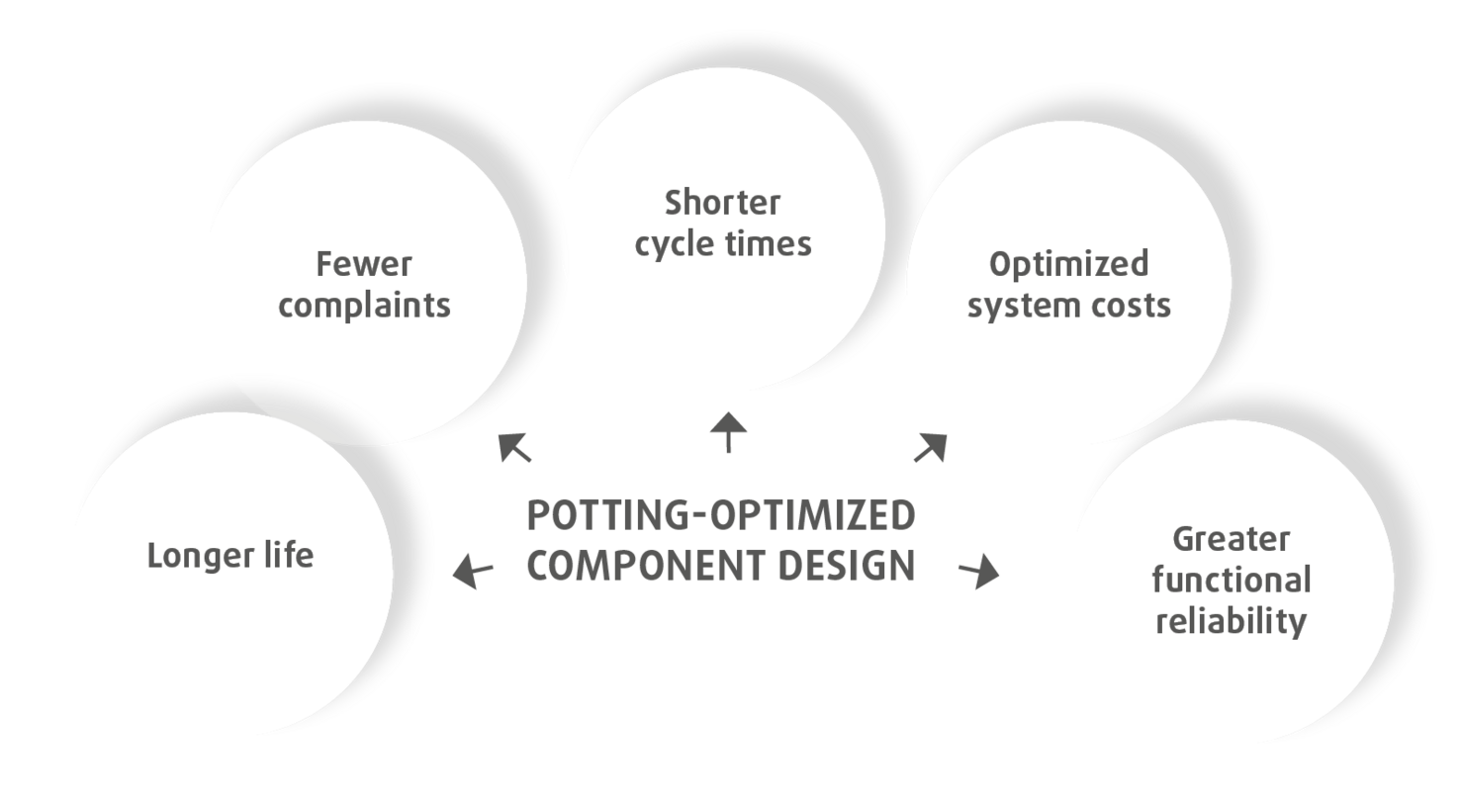

There are various issues that need to be considered in electronic component development, and any conflicts have to be resolved. There are aspects in terms of production and potting, for example. If engineers and product designers take these into account during component development there will be multiple benefits. To achieve the best possible results there needs to be a comprehensive interchange between the system planning, production and after-sales departments so that experience with previous products can be leveraged. The involvement of system and material suppliers is also useful in order not to miss any new, economical design options. If all these aspects are incorporated in the component design, the overall result will also be impressive in terms of total cost of ownership.

There is a dispensing solution for every component

With regard to potting, the design of electronic assemblies and components has a significant impact on economical and sustainable production. Key aspects in this respect are pottability, material use, cycle times, quality and the process technology needed. Optimized, bubble-free potting contributes greatly to the function and longevity of products.

It is best practice during the design and development phases therefore to follow the potting tips contained in this White Paper.