ECONOMICAL AND RELIABLE MATERIAL FEED

Material feed systems delivering viscous media to the dispensing unit have to operate reliably, cleanly and bubble-free while meeting the growing demands for speed, sustainability and economy. The new PailFeed system ensures that medium to high-viscosity materials can be reliably and easily transported from the container to the dispensing unit.

It is available in two versions for abrasive and non-abrasive materials.

Your Benefits

- Material savings thanks to sensor-based residual quantity management

- Speed through fast material supply – material delivery pressure up to 150 bar

- Power for maximum dispensing performance and parallel supply of multiple dispensers

- Flexibility – plant placement possible even over long distances

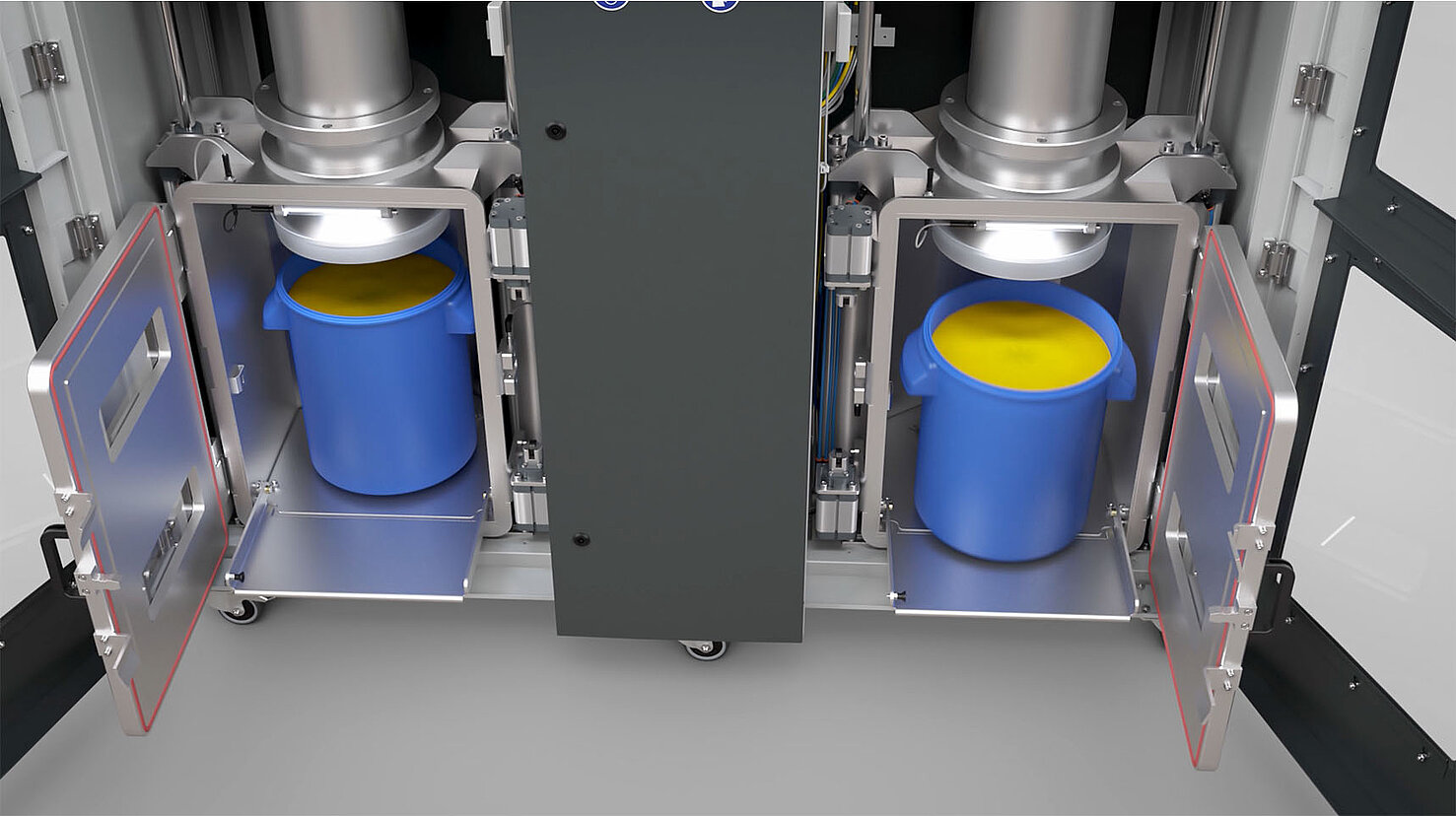

Key Features – Exterior Design

Operating Concept EViS

Dynamic, intuitive visualization of system performance

Central Interface

Simple integration into production environments due to centralized connections

(Compressed air, power supply, communication, material hoses)

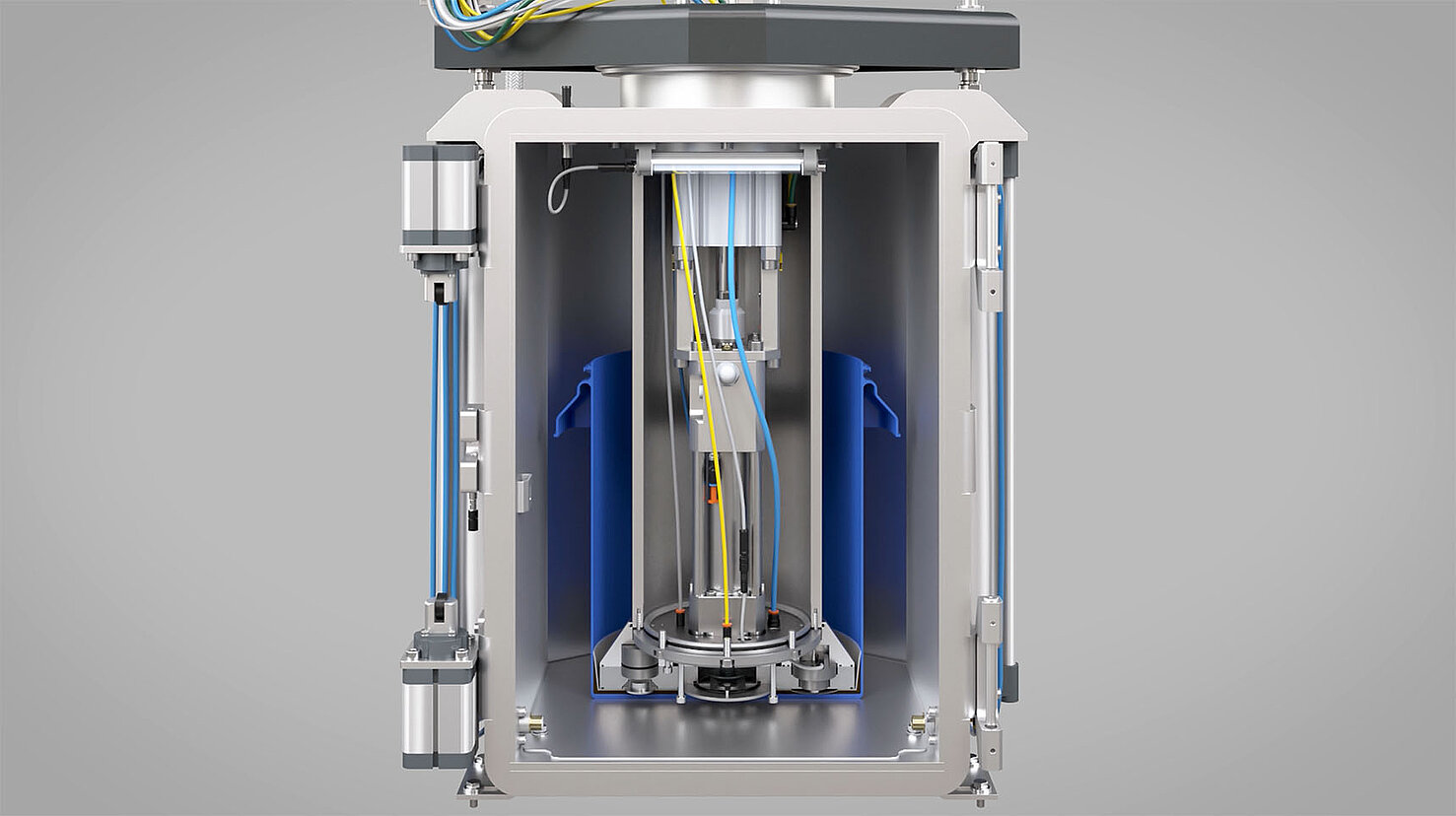

Pump system

delivery pressures of up to 150 bar; viscosity ranging from 50,000 to 3.5 million mPas

Loading drawer

for ergonomic pail changing

Scanner

For error-free pail allocation

Pail positioning

for correct pail placement and process-safe, error-free docking

Vacuum chamber

For the docking of 20-liter pails under vacuum

Key facts

| PFA2001 | PFA2001 | ||

|---|---|---|---|

| 1K | ++ | Filled | ++ |

| 2K | ++ | Abrasive | ++ |

| Atmospheric pressure | ++ | Continuous | ++ |

| Vacuum | (+) | Preparation | - |

| Liquid | (+) | Feeding | ++ |

| Highly viscous | ++ | Systemintegration | ++ |

++ = very good + = good (+) = limited − = not recommended

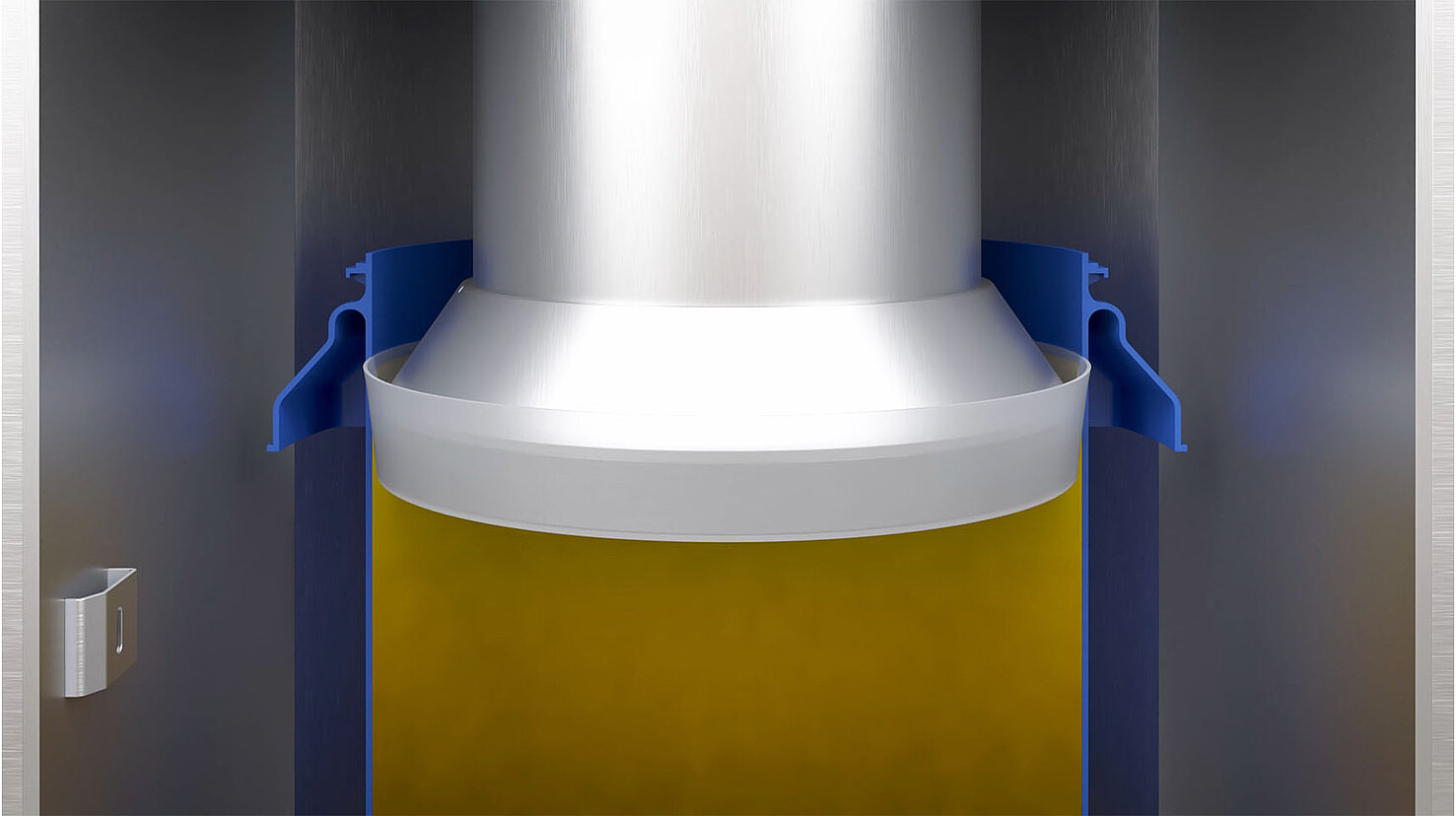

Simple docking – digiTally Monitored

Thanks to intelligent residue management, the consumption of essential, high-cost materials is minimized. The unit is characterized by the combination of a robust reciprocating piston pump and a vacuum chamber. The fully automated docking process takes place under a vacuum to ensure bubble-free feed. Residue management is optimized by a sensor that detects the bottom of the container, thereby avoiding wastage of high-cost materials.

High performance even over long distances

The PailFeed family can handle a wide range of dispensing pressures. There are three different material pressure ranges tailored to the dispensing unit. It delivers up to 150 bar for the new high-Performance dispensers. Several dispensers can be supplied in parallel, quickly and over long distances.

Sustainable SPEED COMBINATION

PailFeed Abrasive PFA2001 not only makes optimum use of materials. It ensures that the dispensing system operates at maximum speed. In combination with the high-performance DosP DP2001 dispenser it achieves short cycle times and optimum dispensing quality.

PERFECTLY INTEGRATED

The PailFeed family has a modern attractive look and feel. It is designed to be stable, securely standing, and seamlessly integrates into the dispensing system. The material feeding system PFA2001 for highly viscous and abrasive media is characterized by its material-saving, high-performance, and economical design.

Monitored for reliability

Stable, state-of-the-art control technology and components ensure that the pail is automatically monitored and that constant material feed pressure is maintained. The control panel is ergonomically located at eye level for digital process monitoring. Touch functionality and a widget-based graphical user interface simplify operation. The performance of the system is always under control thanks to continuous monitoring. Data is collected for subsequent analysis.